Know-howmakes the difference

17

An

Company

B-1210-UK-02-2014-REV.B

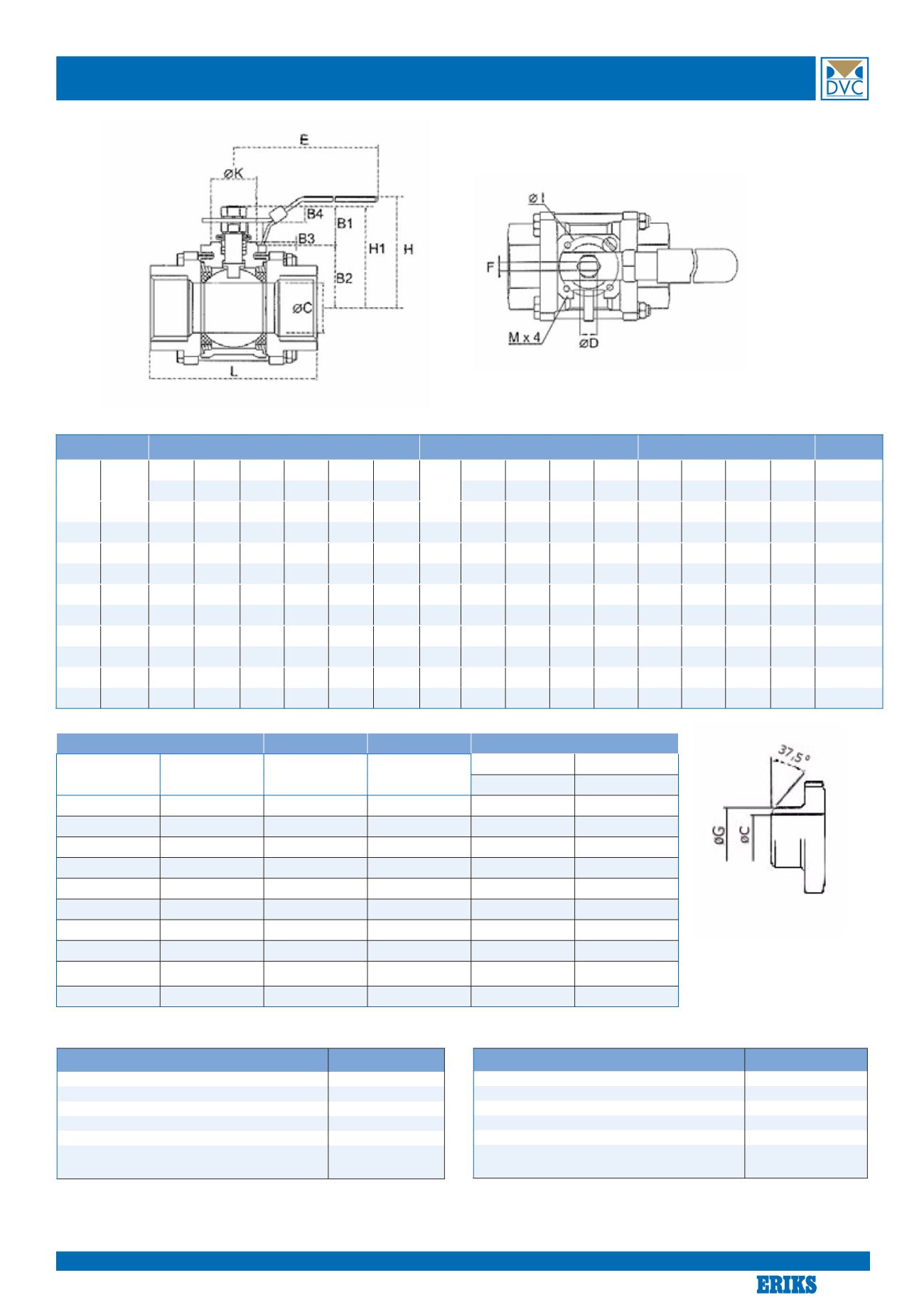

Dimensions type1213 steel and1313 stainless steel

Dim.

Valvewithhandle

ISO topflange

Stem

Kv-value

(mm) (inch)

L

B2 øC E

H H1 ISO

5211

øI

øK Mx4 B3 øD F

B1 B4 Full Open

(mm) (mm) (mm) (mm) (mm) (mm)

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (m3/h)

10 3/8” 63.5 29.5 13 130 65.0 50.5 F03 36 25 M5 2 9.5 6.5 19.5 8.3

6.9

15 1/2” 65.5 29.5 15 130 65.0 50.5 F03 36 25 M5 2 9.5 6.5 19.5 8.3

10.3

20 3/4” 76.2 33.0 20 130 68.0 53.7 F03 36 25 M5 2 9.5 6.5 19.5 8.6

27.5

25 1”

86.0 40.0 25 165 71.0 66.3 F04 42 30 M5 2 11.0 8.0 20.9 13.7 48.2

32 1 1/4” 102.8 41.0 32 165 78.0 65.9 F04 42 30 M5 2 11.0 8.0 25.3 13.8 70.5

40 1 1/2” 119.0 47.5 38 190 86.0 80.7 F05 50 35 M6 2 14.0 9.7 31.5 14.6 103.2

50 2”

131.4 55.0 50 190 95.0 88.0 F05 50 35 M6 2 14.0 9.7 31.5 14.6 207.0

65 2 1/2” 164.0 75.0 65 250 130.0 119.3 F07 70 55 M8 2 19.0 12.0 41.2 26.7 275.0

80 3”

182.5 85.0 80 250 148.0 125.8 F10 102 70 M10 2 19.0 12.0 41.4 21.9 499.0

100 4”

235.6 108.0 100 280 185.0 161.8 F10 102 70 M10 2 24.0 15.0 51.0 33.0 877.0

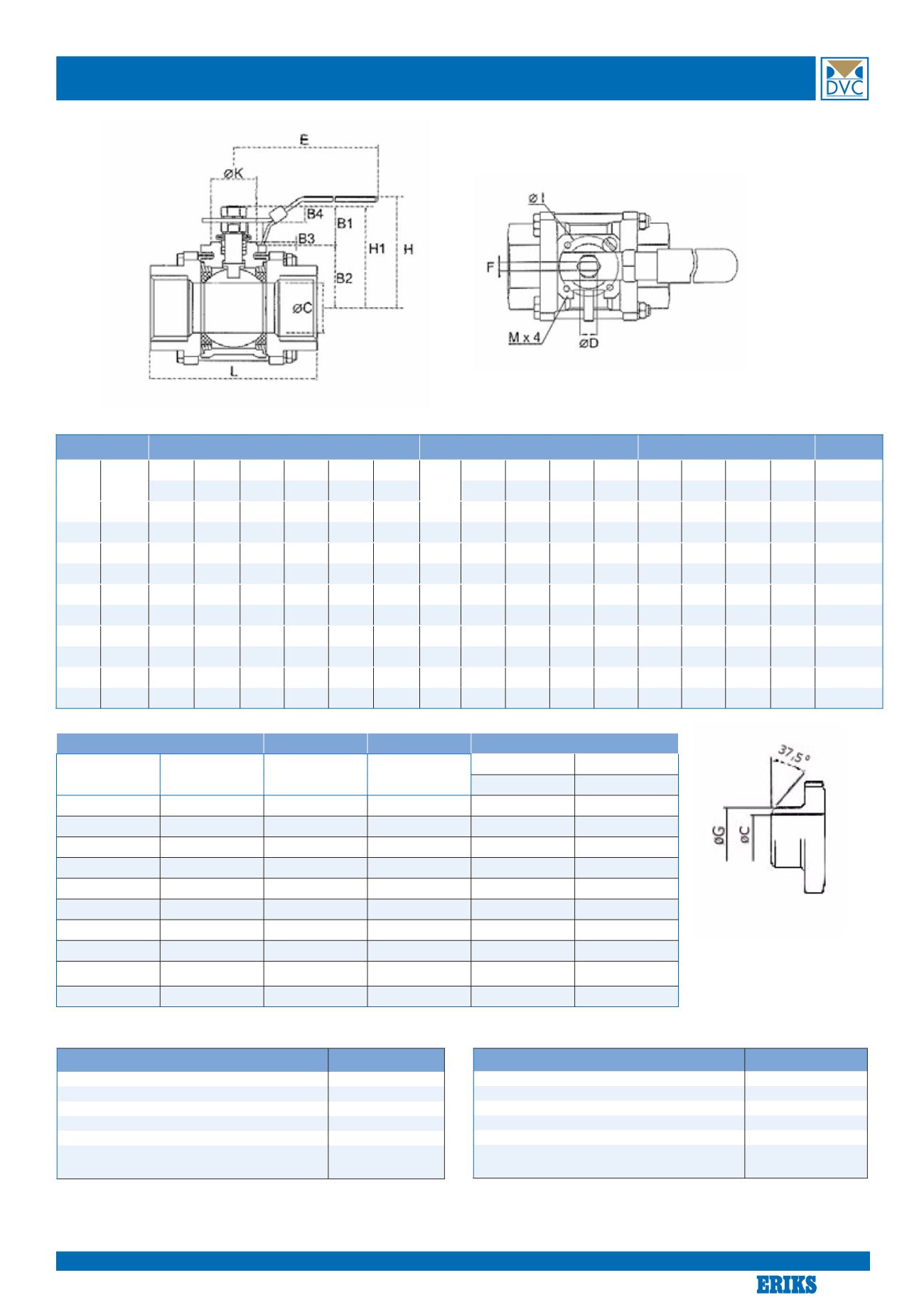

Dim.

1) Torque

Weight

Buttweld ends

(mm)

(inch)

(Nm)

(kg)

Type 1213

Type 1313

øG / øC

øG / øC

10

3/8”

9.6

0.40

17.2 / 12.7

17.2 / 14.0

15

1/2”

9.6

0.60

21.3 / 15.0

21.3 / 18.1

20

3/4”

10.8

0.80

26.9 / 20.5

26.9 / 23.7

25

1”

20.4

1.10

33.7 / 25.7

33.7 / 29.7

32

1 1/4”

21.6

1.70

42.4 / 34.4

42.4 / 38.4

40

1 1/2”

36.0

2.60

48.3 / 40.3

48.3 / 44.3

50

2”

46.8

3.20

60.3 / 51.3

60.3 / 55.1

65

2 1/2”

73.2

7.40

76.1 / 67.1

76.1 / 70.9

80

3”

102.0

11.20

88.9 / 80.0

88.9 / 83.7

100

4”

156.0

20.30

114.3 / 103.1 114.3 / 109.1

MEDIA FACTOR

MULTIPLIER

Clean, particle free, non-lubricating (water, alcohol, etc)

1.00

Clean, particle free, lubricating (oils, hydraulic fluid, etc)

0.80

Slurries or heavily corroded, solvents and contaminated systems

2.00#

Gas or saturated steam, clean andwet

1.00

Gas or superheated steam, clean and dry

1.30

Gas, dirty unfiltered e.g. natural gas, Chlorine

1.50

SERVICE FACTOR

MULTIPLIER

Simple On andOff Operations

1.00

Throttling

1.20

Positioner Control

1.50

Once per day Operations

1.20

Once every two days or a “Plant Critical” Operation

1.50

Max differential pressure

(DN08-32) 1.50

(DN40-65) 2.00

(DN80-100) 2.80

*) Torque figures included 30% safety factor. (TEST: 0bar diff. pressure, ambient temperature, Non-lubricating)

When dimensioning the actuator followingmust be added: - 15% if lubricatingmedias.

Basic Torque*Media Factor *Service Factor = Sizing Torque

#Usingball valves in contaminated systemswill reduce life time