14

Know-howmakes the difference

B-1210-UK-02-2014-REV.B

An

Company

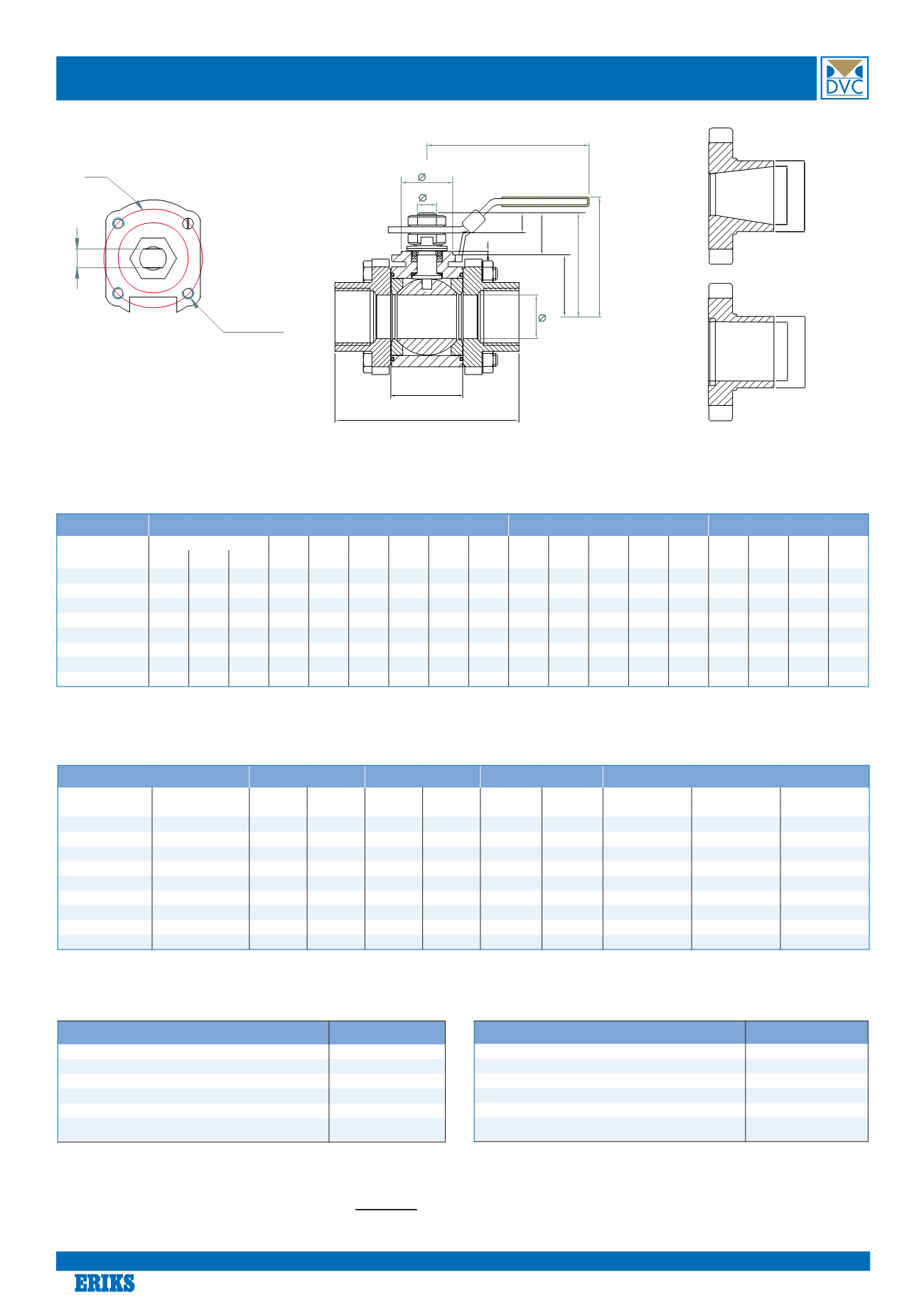

Dimensions type1210 steel and1310 stainless steel

L

H

H1

B2

B1

B4

B3

E

D

C

K

L2

ISO5211

F

Mx4

(G)

*) Torque figures include 30% safety factor. (TEST: 0bar diff. pressure, ambient temperature, non-lubricating)

When dimensioning the actuator followingmust be added:

ød øG

ød øG

Dimension

valvewithhandle

iso topflange

stem

[mm]

L [mm]

L2

B2

øC

E

H

H1

ISO

5211

G

K

Mx4

B3

øD

F

B1

B4

Thread BW SMS [mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

DN08FB

64,8 64,8 64,8 24.5 29,8

10

134 64,3 37,2 F03

36

25

M5

0,5

9,5

6,5

7,4

6,1

DN10FB / DN15RB 64.8 64.8 64.8 24.5 29.8

10

134 64.3 37.2 F03

36

25

M5

0.5

9.5

6.5

7.4

6.1

DN15FB / DN20RB 72.5 75.0 75.0 24.5 29.0

15

134 71.5 45.1 F03

36

25

M5

2.0

9.5

6.5

16.1

7.3

DN20FB / DN25RB 85.4 89.8 89.8 31.4 33.0

20

134 76.0 51.1 F03

36

25

M5

2.0

9.5

6.5

18.1

8.8

DN25FB / DN32RB 105.3 109.4 109.4 41.3 36.0

25

170 82.3 60.6 F04

42

30

M5

2.0

11.1

8.0

24.6 11.0

DN32FB / DN40RB 111.0 114.4 114.4 48.4 40.0

32

170 87.3 64.3 F04

42

30

M5

2.0

11.1

8.0

24.3

9.7

DN40FB / DN50RB 127.3 130.0 130.0 56.3 47.3

38

207 103.6 77.5 F05

50

35

M6

2.0

14.3

9.7

30.2 12.2

DN50FB / DN 65RB 145.0 145.0 145.0 71.4 69.5

50

207 121.6 95.0 F05

50

35

M6

2.0

14.3

9.7

30.2 12.2

Dimension

*) Basic Torque

Weight

kv-values

Buttweld ends

[mm]

[inch]

FB [Nm]

RB [Nm]

FB [kg]

RB [kg]

FB 90°m³/t RB 90°m³/t

Type 1210

Type 1310

SMS3008

øG xmm (ød)

øG xmm (ød)

øG xmm (ød)

DN08

1/4”

9.6

-

0.80

-

6.9

-

13.7 x 3.2 (7.3)

13.5 x 1.6 (10.3)

10.0 x 1.0 (8.0)

DN10

3/8”

9.6

9.6

0.80

0.66

6.9

6.9

17.5 x 3.2 (11.1)

17.2 x 1.6 (14.0)

12.0 x 1.0 (10.0)

DN15

1/2”

10.8

9.6

0.82

0.66

12.7

6.9

21.3 x 3.2 (14.9)

21.3 x 1.6 (18.1)

18.0 x 1.0 (16.0)

DN20

3/4”

14.4

10.8

1.28

0.87

29.2

12.7

26.9 x 3.2 (20.5)

26.9 x 1.6 (23.7)

25.0 x 1.2 (22.6)

DN25

1”

19.2

14.4

2.07

1.36

48.2

29.2

33.7 x 4.0 (25.7)

33.7 x 2.0 (29.7)

32.0 x 1.2 (29.6)

DN32

1 1/4”

31.2

19.2

2.65

2.01

73.1

48.2

42.4 x 4.0 (34.4)

42.4 x 2.0 (38.4)

33.7 x 1.2 (31.3)

DN40

1 1/2”

40.8

31.2

3.79

2.69

107.5

73.1

48.3 x 4.0 (40.3)

48.3 x 2.0 (44.3)

38.0 x 1.2 (35.6)

DN50

2”

57.6

40.8

5.51

4.04

215.0

107.5

60.3 x 4.5 (51.3)

60.3 x 2.0 (56.3)

51.0 x 1.2 (48.6)

DN65

2 1/2”

-

57.6

-

6.78

-

215.0

76.1 x 4.5 (67.1)

76.1 x 2.6 (70.9)

63.5 x 1.6 (60.3)

MEDIA FACTOR

MULTIPLIER

Clean, particle free, non-lubricating (water, alcohol, etc)

1.00

Clean, particle free, lubricating (oils, hydraulic fluid, etc)

0.80

Slurries or heavily corroded, solvents and contaminated systems

2.00#

Gas or saturated steam, clean andwet

1.00

Gas or superheated steam, clean and dry

1.30

Gas, dirty unfiltered e.g. natural gas, Chlorine

1.50

Basic Torque*Media Factor *Service Factor = Sizing Torque

SERVICE FACTOR

MULTIPLIER

Simple On andOff Operations

1.00

Throttling

1.20

Positioner Control

1.50

Once per day Operations

1.20

Once every two days or a “Plant Critical” Operation

1.50

Max differential pressure

(DN08-32 PN125) 1.50

(DN40-65 PN100) 2.00

EXAMPLE:

1310DN25FB, Natural gas, Positioner Control.

19,2[Nm] *1.5*1.5=43.2Nm (Sizing Torque)

#Usingball valves in contaminated systemswill reduce life time