B-2232-UK-09-2013-REV. A

An

Company

Check that the specifications on the identification plate meet the require-

ments regarding pressure, temperature and media.

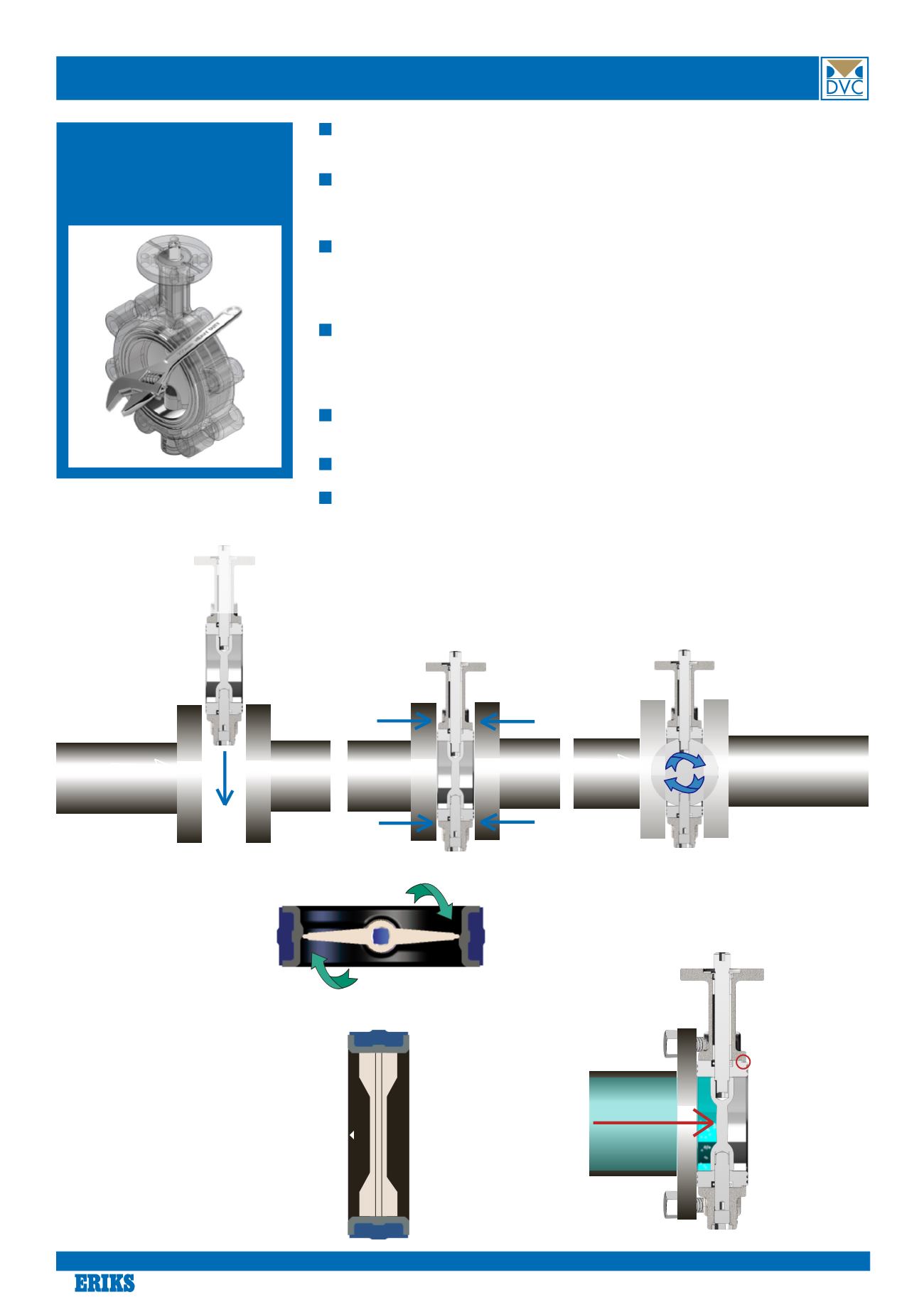

The piping must have a straight line and the flanges have to be parallel.

Furthermore there must be a distance between the flanges, corresponding

to the face-to-face dimensions of the butterfly valve.

The butterfly valve can be mounted in any direction. However if there are

a lot of dirt particles on the bottom of the pipe, it will be suitable to mount

the stem of the butterfly valve horizontally. This will protect the pivot point

of the disc.

Before commissioning, the pipe work has to be rinsed out to remove dirt

and remnants of welding material, to avoid damage on the liner. During the

rinsing procedure, the butterfly valve has to be positioned as open and may

not be operated, before the rinsing has been completed.

Welding operations may not be performed nearby the butterfly valve, as

welding drops can damage the liner.

Do not use gaskets. The liner works as sealing to the atmosphere.

Where vacuum, high flow rate or water hammering can occur, flanges with-

out a loose collar should be used, to obtain the best conditions.

Installation guide for

Butterfly Valves

Check that the flange covers

the area of the liner.

Afterwards tighten the bolts

on the flange by hand.

Carefully open and close the

valve to check that the disc

centralizes and the disc does not

touch the flange. With the disc

in the open position, tighten

crosswise with a wrench.

Though the valves are constructed

to work as shown on the right,

counter clockwise rotation - CCW

- they can be reversed without

problems. Please consider that the

torque in this case will increase.

As the butterfly valves are

equipped with the unique wave

shaped liner, the operation of the

valves, either free stem, handle or

gear operated, has to follow the

guidelines as shown below.

A small triangular shaped figure is

placed on the liner - this triangle

indicates which way the disc has to

enter the liner.

Generally spoken the disc has to

close clockwise - CW - in order to

have the lowest possible torque -

and thus the longest possible life

time.

Installation guide

Turn disc

CW towards

arrow to

close

Turn 90

°

CW to close

Carefully place the but-

terfly valve between the

flanges, with the disc in

closed position.

2242 LUG, used as an “end of line” valve:

Please notice that the valve is uni-directional.

14

Know-how makes the difference