B-2232-UK-09-2013-REV. A

An

Company

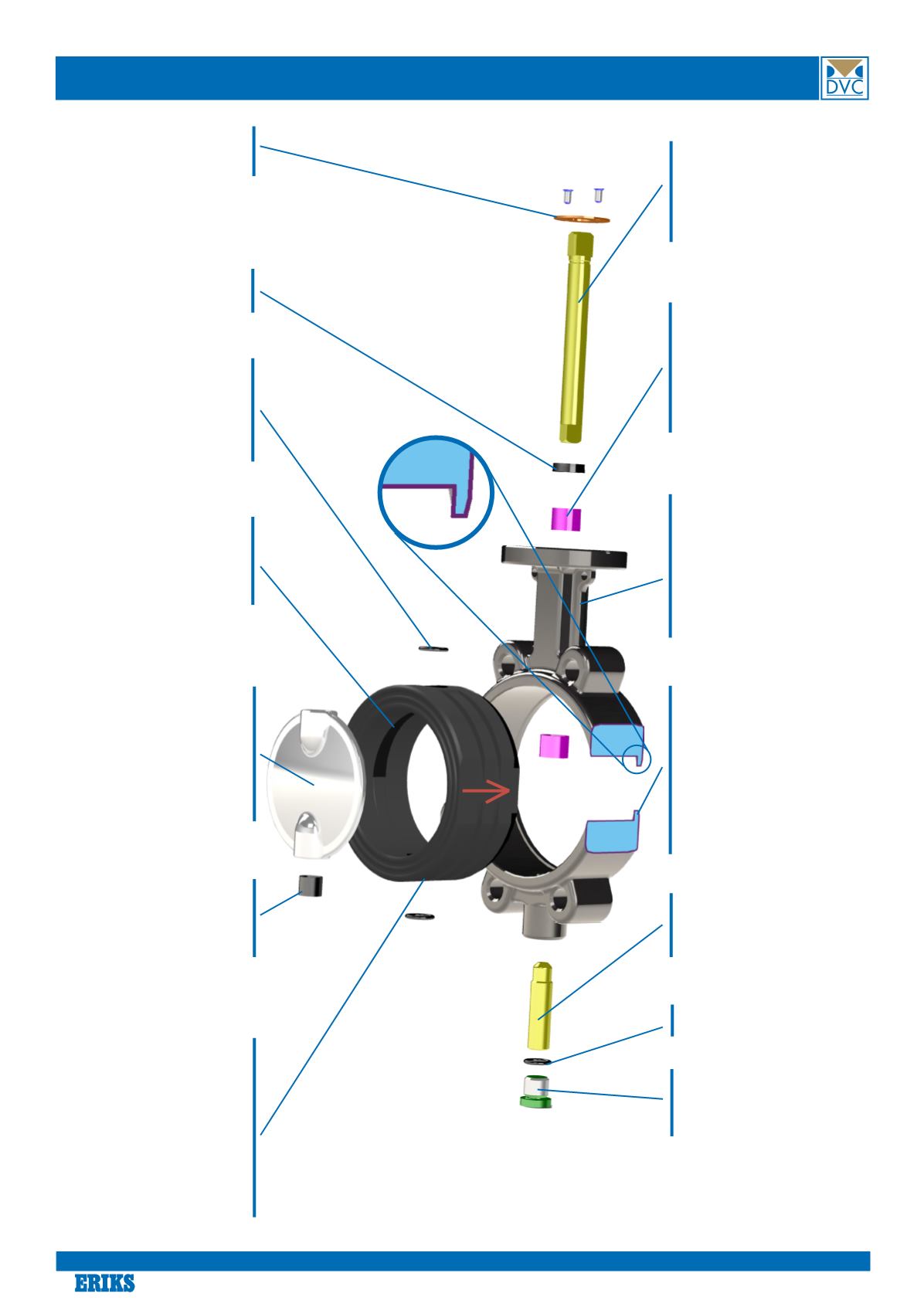

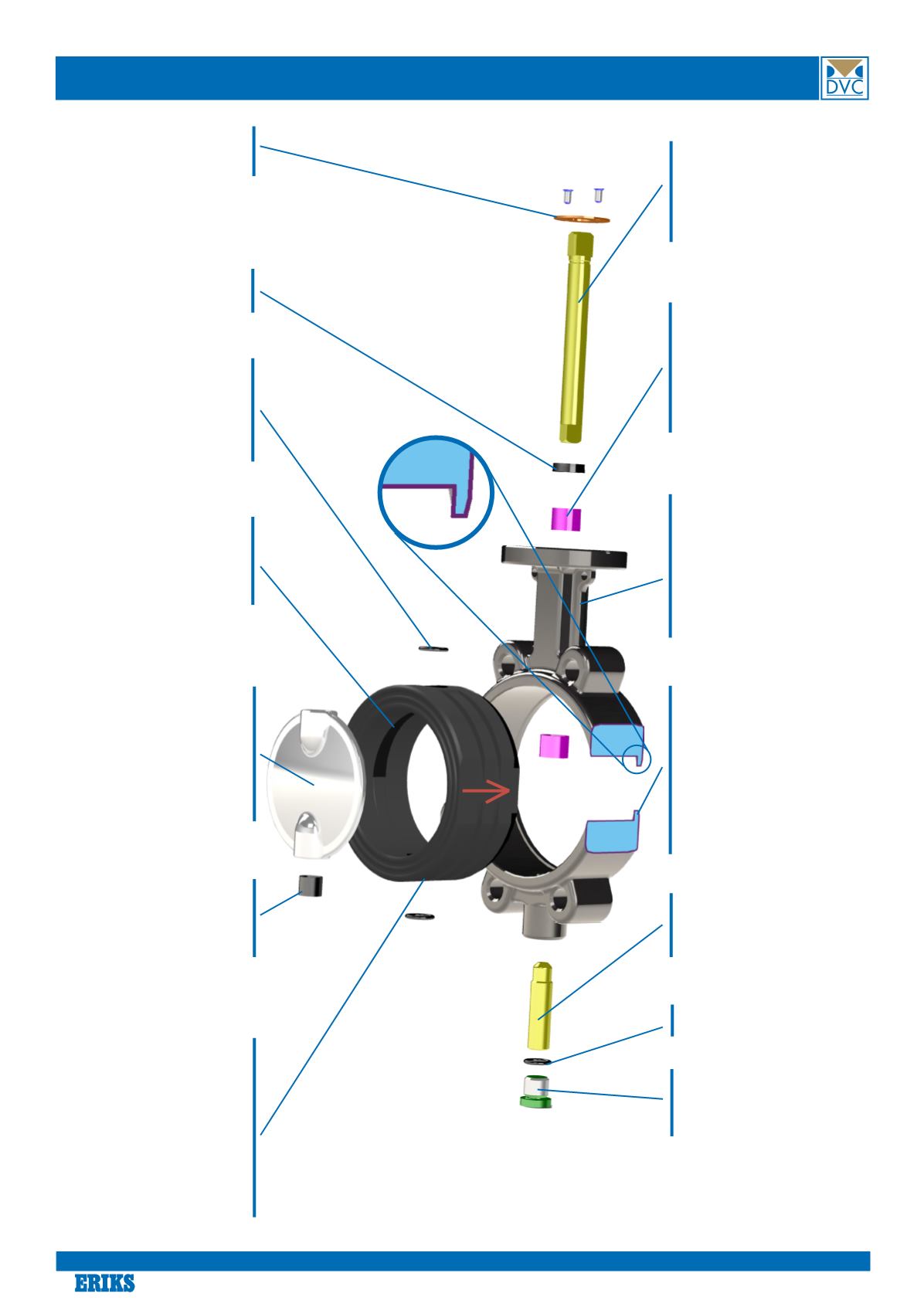

Construction

Stainless steel disc

ensures blow-out proof

stem

V-ring provides a weather

seal

O-ring as secondary seal-

ing ensures that media

does not escape to the

atmosphere through the

stem guide

Disc with two-piece shaft

construction enhances the

flow capacity of the valve.

The shape of the disc

provides lower torque and

prolongs the life span of

the valve

PTFE/graphite bearing

ensures perfect turning

and centric positioning of

the stem. The bearing is

placed inside the disc

Seat vulcanized to a

phenol back-up ring which

makes seat replacement

very easy. The tolerances

assure 100% tightness

at full differential pres-

sure. The valve is ideal for

vacuum applications and

mounting between flanges

is easily done

Square stem - angled at

45°. Material is AISI 420

or AISI 431 to insure high

torque transmission with-

out damage. Smooth finish

surface

PTFE bearing ensures

perfect turning and centric

positioning of the stem.

The sleeve bearing pro-

vides excellent support

if actuators are used for

automation purposes

High quality GGG40 steel

body with standard ISO

5211 mounting flange.

Body is coated according

to ISO 12944 C3 industrial

standard with 3 layer

Epoxy/Epoxy/PUR 160µ

Both Wafer and LUG has

fully changeable liner con-

struction.

LUG model has a specialy

designed grove to insure

uni-directional “end of line”

installation with full differ-

ential pressure

O-ring anti-dust type

Bottom plug ensures blow-

out proof design and acts

as a weather seal

Bottom stem in AISI 420 or

AISI 431 with smooth sur-

face finish

Unique seat wave line

rubber seat reduces the

torque of the valve and

extends the life span of

the sealing. DN40-DN300

4

Know-how makes the difference