12

Know-how makes the difference

B-V-NOTCH-UK-02-2014 REV. C

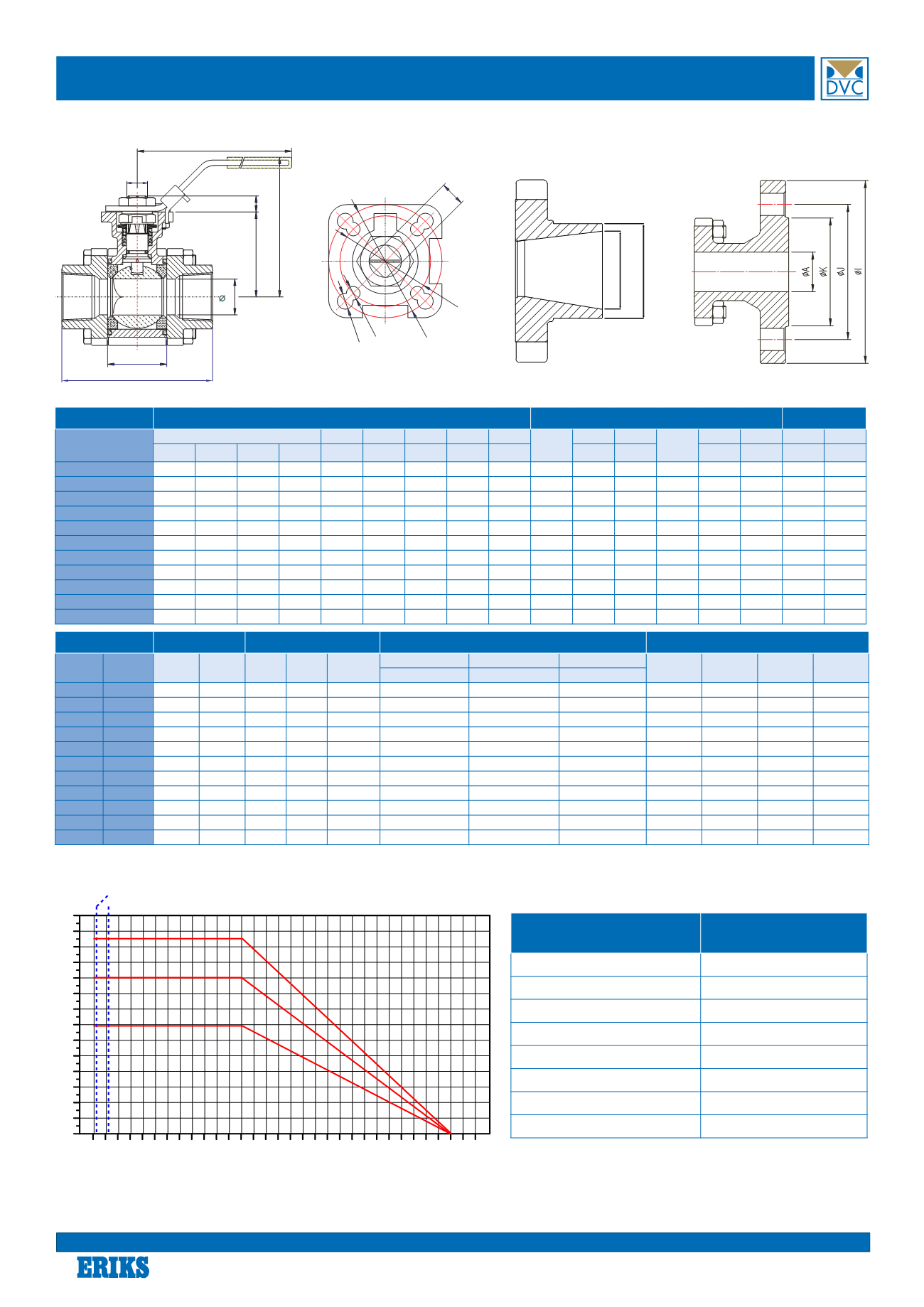

An

Company

E

øD

H

B1

B2

C

+0.8

+0.2

L2

L

-+1

øX2

øX1

øM2

øM1

F

ød

øG

TYPE 1211 / 1311 WITH ISO-TOP FOR DIRECT ACTUATOR MOUNTING

Dimension

Valve with handle

ISO top flange

Stem

[mm]

L [mm]

L2

B2

øC

E

H

ISO

5211

øM1 øX1x4 ISO

5211

øM2 øX2x4

F

B1

Gevind Svejse SMS Flange [mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

DN08FB

75.0 75.0 75.0

-

24.5 42.6 11.5

139

77.0

F03

36

6.0

F04

42

6

9

7.6

DN10FB / DN15RB

75.0 75.0 75.0

-

24.5 42.6 12.6

139

77.0

F03

36

6.0

F04

42

6

9

7.6

DN15FB / DN20RB

72.5 75.0 75.0

130

24.5 42.6 15.0

139

77.0

F03

36

6.0

F04

42

6

9

7.6

DN20FB / DN25RB

85.4 90.0 90.0

150

31.4 46.9 20.0

139

82.0

F03

36

6.0

F04

42

6

9

8.6

DN25FB / DN32RB

105.3 110.0 110.0 160

41.3 59.3 25.0

165

98.5

F04

42

6.0

F05

50

7

11

10.4

DN32FB / DN40RB

111.0 115.0 115.0 180

48.4 62.6 32.0

165 102.0 F04

42

6.0

F05

50

7

11

10.4

DN40FB / DN50RB

127.3 129.6 129.6 200

56.3 79.0 38.0

215 128.0 F05

50

6.0

F07

70

9

14

13.4

DN50FB / DN65RB

145.0 145.0 145.0 230

71.4 87.7 50.0

215 137.0 F05

50

7.5

F07

70

9

14

13.4

DN65FB / DN80RB

185.0 185.0 185.0 290

86.6 108.7 65.0

262 167.0 F07

70

7.5

F10

102

12

17

16.8

DN80FB / DN100RB

205.0 205.0 205.0 310

99.0 117.7 76.0

262 176.0 F07

70

10.0

F10

102

12

17

17.8

DN 100FB

240.0 240.0 240.0 350 127.0 133.7 100

312 192.0 F07

70

10.0

F10

102

12

17

16.8

Dimension

*) Torque

Weight

Butt weld ends

Flange ends

[mm]

[tomme]

FB

[Nm]

RB

[Nm]

FB

[kg]

RB

[kg]

FB flanger

[kg]

Type 1211

Type 1311

SMS3008

øA [mm]

øK [mm]

øJ

[mm]

øI

[mm]

øG / ød (mm)

øG / ød (mm)

øG / ød (mm)

DN08

1/4”

9

-

0.89

-

-

13.7 / 7.3 (3.2)

13.5 / 10.3 (1.6)

10.0 / 8.0 (1.0)

-

-

-

-

DN10

3/8”

9

-

0.88

-

-

17.5 / 11.1 (3.2)

17.2 / 14.0 (1.6)

12.0 / 10.0 (1.0)

-

-

-

-

DN15

1/2”

9

9

0.82 0.84

2.34

21.3 / 14.9 (3.2)

21.3 / 18.1 (1.6)

18.0 / 16.0 (1.0)

15

45

65

95

DN20

3/4”

12

9

1.29 0.85

3.47

26.9 / 20.5 (3.2)

26.9 / 23.7 (1.6)

25.0 / 22.6 (1.2)

20

58

75

105

DN25

1”

17

12

2.01 1.41

4.66

33.7 / 25.7 (4.0)

33.7 / 29.7 (2.0)

32.0 / 29.6 (1.2)

25

68

85

115

DN32

1 1/4”

26

17

2.76 2.17

6.63

42.4 / 34.4 (4.0)

42.4 / 38.4 (2.0)

33.7 / 31.3 (1.2)

32

78

100

140

DN40

1 1/2”

35

26

4.21 2.87

8.64

48.3 / 40.3 (4.0)

48.3 / 44.3 (2.0)

38.0 / 35.6 (1.2)

38

88

110

150

DN50

2”

49

35

5.83 4.49

12.20

60.3 / 51.3 (4.5)

60.3 / 56.3 (2.0)

51.0 / 48.6 (1.2)

50

102

125

165

DN65

2 1/2”

68

49

11.00 6.94

21.00

76.1 / 67.1 (4.5)

76.1 / 70.9 (2.6)

63.5 / 60.3 (1.6)

65

122

145

185

DN80

3”

101

68

14.78 12.64 28.90

88.9 / 78.9 (5.0)

88.9 / 83.7 (2.6)

76.1 / 72.9 (1.6)

80

138

160

200

DN100

4”

124

101

23.30 16.00 40.05 114.3 / 103.1 (5.6) 114.3 / 109.1 (2.6) 101.6 / 97.6 (2.0)

100

162

190

235

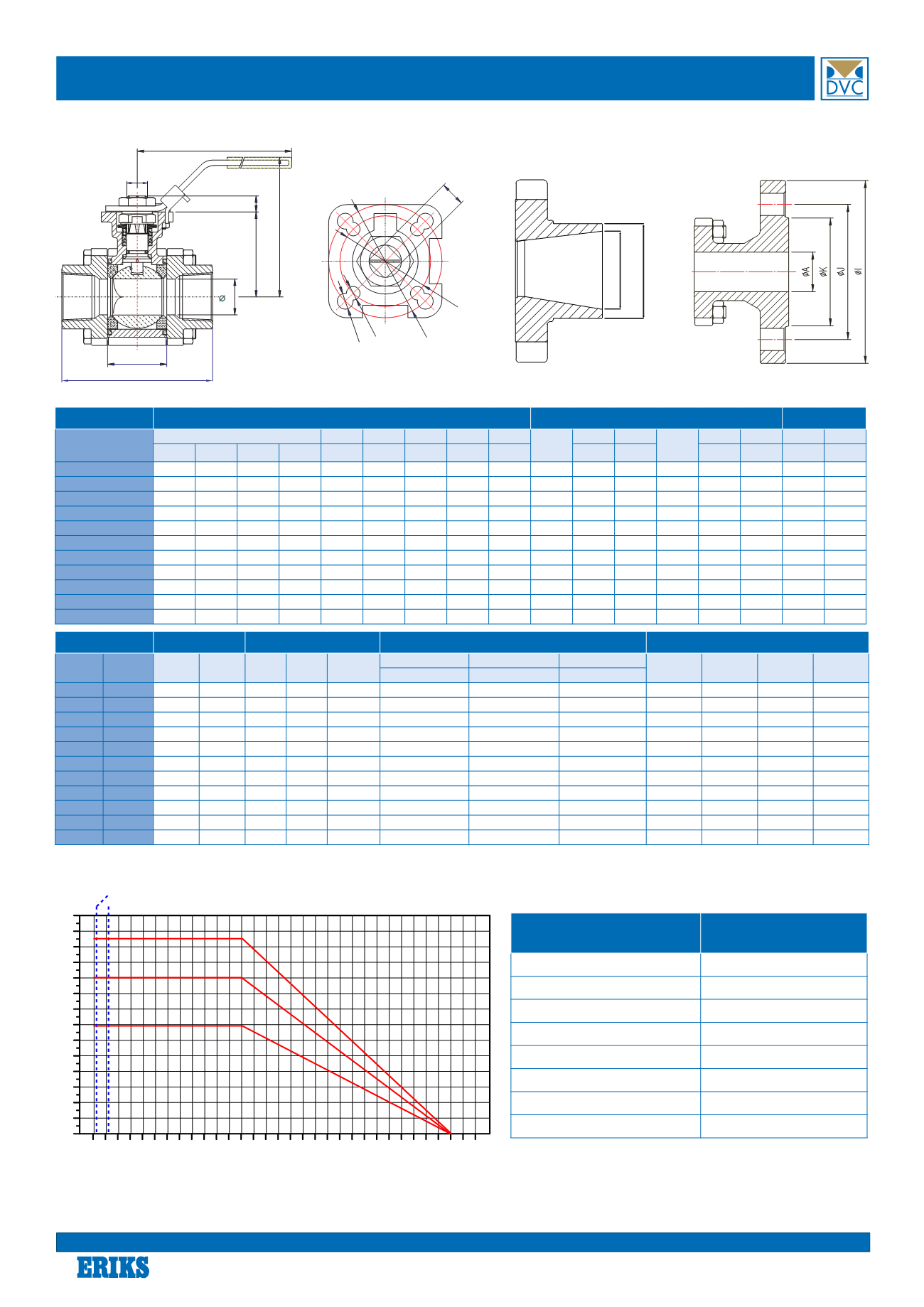

3-PCS BALL VALVE - FOR V-NOTCH BALL

Temperatur i [°C]

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

-28° WCB

-38° AISI316

Bar

-40 -20 0 20 40 60 80 100 120 140 160 180 200 220 240 260

DN8 - DN25 FB

DN65 - DN100 FB

DN32 - DN50 FB

PRESSURE / TEMPERATURE (SEATS PTFE + 25% C)

OTHER SEAT MATERIALS ON REQUEST

Material

Max temperature

[0barg]

DELRIN

85

o

C

UHMWPE

85

o

C

PTFE “VIRGIN”

190

o

C

RPTFE

195

o

C

MG1241

215

o

C

PTFE + 50% SS

230

o

C

PTFE + 25% CARBON *

250

o

C

PEEK **

270

o

C

* PTFE + 25%C are DVC standard seat material for TYPE 1210/1310 and 1211/1311 3-pcs ball valve. During years of experience DVC advises this

seat material as being the most wear resistance material. This combined with the high temperature span covers 95% of all usages.

**Using PEEK (Ceramic reinforced PTFE) as a seat material causes higher breakaway torque. At particular valve sizes, due to torque, the stem

material has to be changed from AISI316 to 17-4PH which is a harder material. Please consult DVC if any questions regarding other seats material.

* Torgue figures with 30 % safety factor included.